Octagonal Paper Box Forming Machine

The Octagonal Paper Box Forming Machine is an advanced, fully automatic machine designed for high-speed production of sturdy paper lunch boxes. It efficiently performs automatic paper feeding, folding, gluing, and forming, ensuring precision and durability. With microcomputer control and stable mechanical operation, it enhances productivity while reducing manual labor. Ideal for food packaging industries, this machine provides a reliable, eco-friendly solution for disposable lunch box manufacturing.

NS-EC50

Speed

70 Pcs/Min

Paper Specification

200-500 Gsm

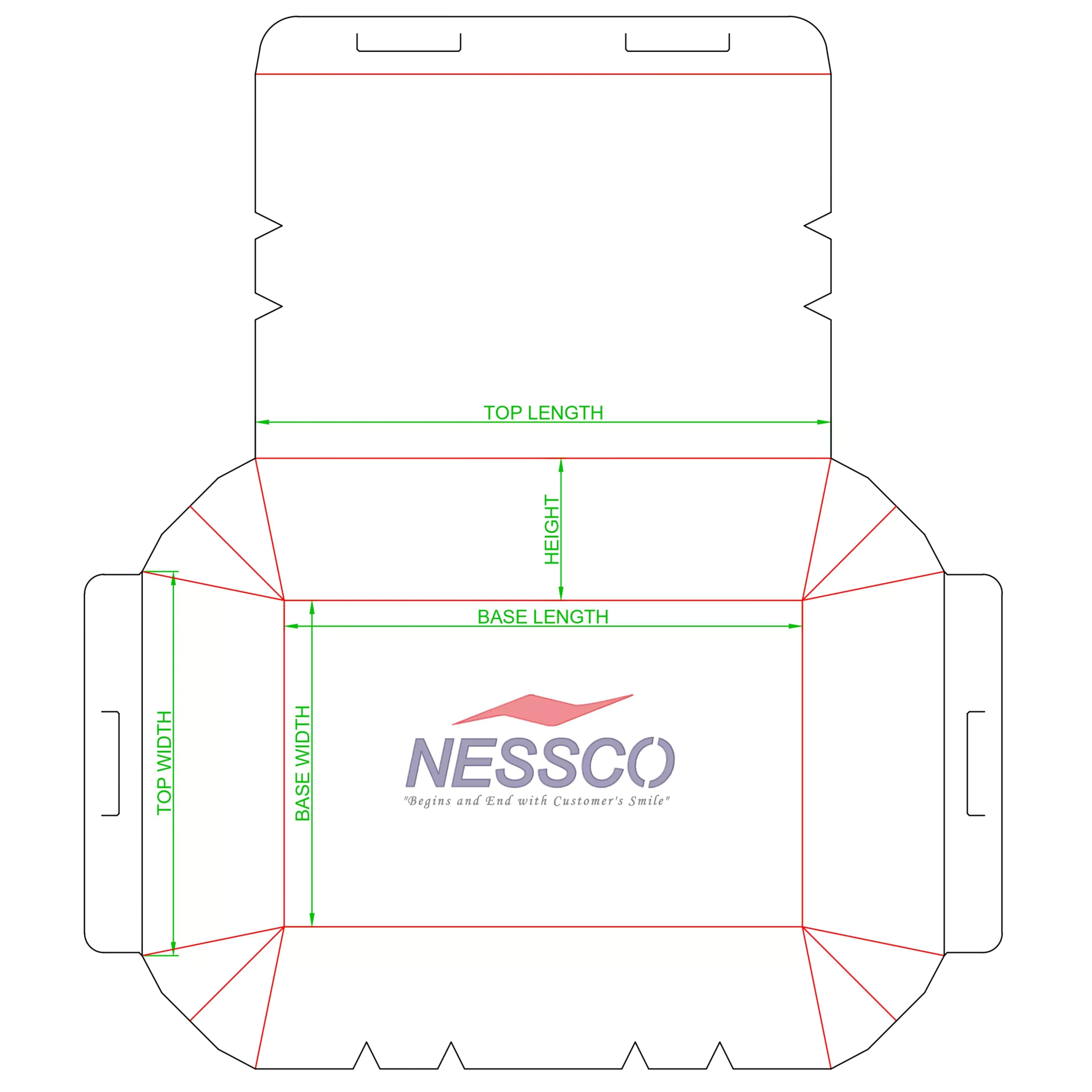

Size Range

10Oz/300Ml-40Oz/1200Ml

A Octagonal Paper Box Forming Machine is a fully automatic equipment designed to produce single or double PE-coated paper trays. This versatile machine can also manufacture other paper products such as square paper bowls, lunch boxes, baking cups, and various square containers by simply switching molds. It operates as a multi-station machine, controlled by a microcomputer that ensures precise functioning. The machine is equipped with a servo system for automatic paper feeding, hydraulic forming, and counting, which enhances efficiency and consistency in production. This type of machine is widely used in food service and packaging industries for creating high-quality, eco-friendly paper containers.

Speed

70 Pcs/Min

Paper Specification

200-500 Gsm

Range

10Oz/300Ml-40Oz/1200Ml

Technical Specifications

| FEATURE | SPECIFICATION |

|---|---|

| Speed | 70 Pcs/Min |

| Paper Specifications | 200-500 Gsm |

| Raw Materials | Single PE.,Craft Paper |

| Size | 10Oz/300Ml-40Oz/1200Ml |

| Voltage | 380-400VAC |

| General Power | 8 kW |

| Weight | 1500 Kg |

| Dimensions | 2438X1208X1524 (mm) |

| Air Pressure | 6-8 Bar |

| Air Flow Rate | 20 Cfm |

Process of Cup Formation

1. Automatic Paper Feeding

The machine automatically picks and feeds pre-cut paper sheets into the system, ensuring a continuous and efficient workflow.

2. Folding & Shaping

The paper sheets are precisely folded into the required box shape using mechanical guides and forming tools, ensuring uniformity.

3. Gluing & Sealing

A high-quality adhesive system applies glue to secure the box structure, followed by a sealing process to ensure durability and strength.

4. Final Shaping & Pressing

The boxes undergo a pressing mechanism to reinforce their shape, ensuring they are sturdy and ready for food packaging.

5. Collection & Stacking

The finished lunch boxes are automatically counted, stacked, and prepared for packaging, making the process seamless and efficient.

Applications

Want to Know More? Enquire Now

.webp&w=3840&q=75)

.webp&w=3840&q=75)

.webp&w=3840&q=75)